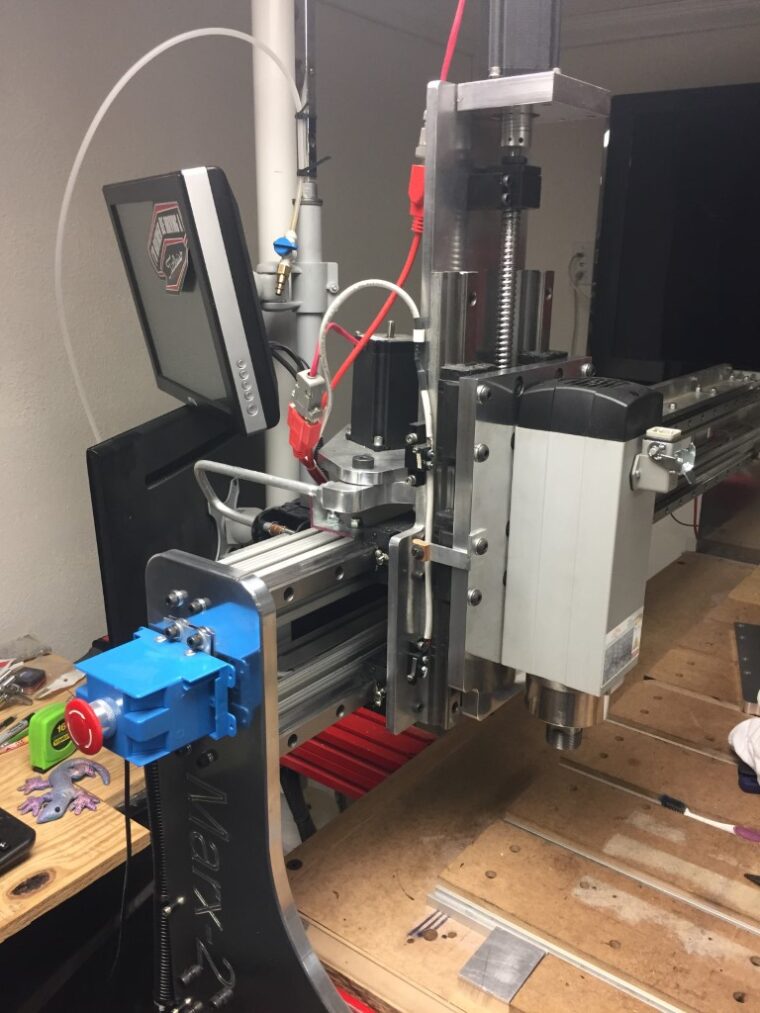

Now that the CNC is up and running its time for a few upgrades… the first being a spindle instead of a wood router. The addition of a spindle will allow for more torque and consistent cutting speeds, the torque will increase when using at 220v instead of 110v. I’m sure there are lots of discussions around what creates torque but in my mind upping the voltage to 220v is the biggest factor.

I did some research to narrow down the choices from among some of the Chinese manufacturers. The Chinese seems to be the most affordable and widely used choices. My requirements for a spindle are – 18K RPM range, ER25 collet and air cooled. I don’t want to mess with water cooling and most of my run times wouldn’t benefit anyway, here was the list I created.

As you can imagine like everything from China there are a lot of different manufacturers selling the same spindle and labeling it as their own, so just be cautious. I essentially used model# as the differentiator but also compared the other features.